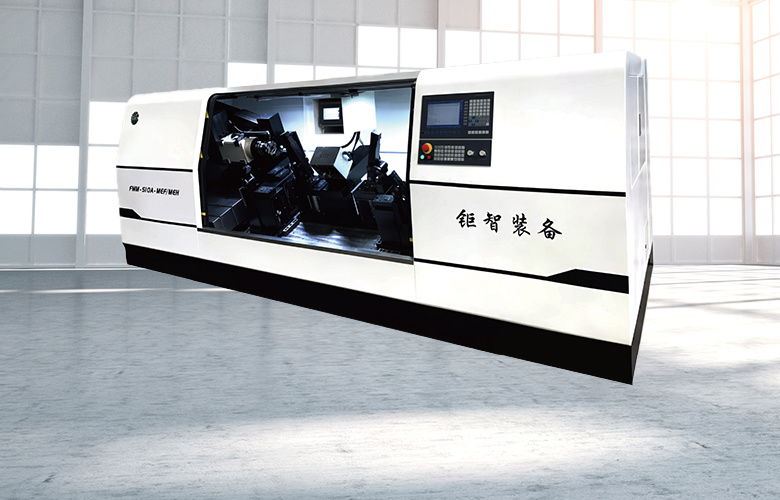

Frame milling machine

Category:

Product Description

Function Description

• Automatic detection of margin distribution before processing, in the case of meeting the size, with the minimum amount of milling processing;

• automatically detect the inclination angle and beam angle values of the end face after finishing, save the detection data for a long time, and mark after passing the detection;

• The machining data of the beam angle and inclination angle of the milling end face can be adjusted by the servo motor, and the adjustment range is 3 °;

• Full CNC servo feed system, the feed position of the milling surface can be adjusted freely;

• Table 25 ° slope design, supporting chip removal machine, to achieve automatic chip removal function.

Equipment composition

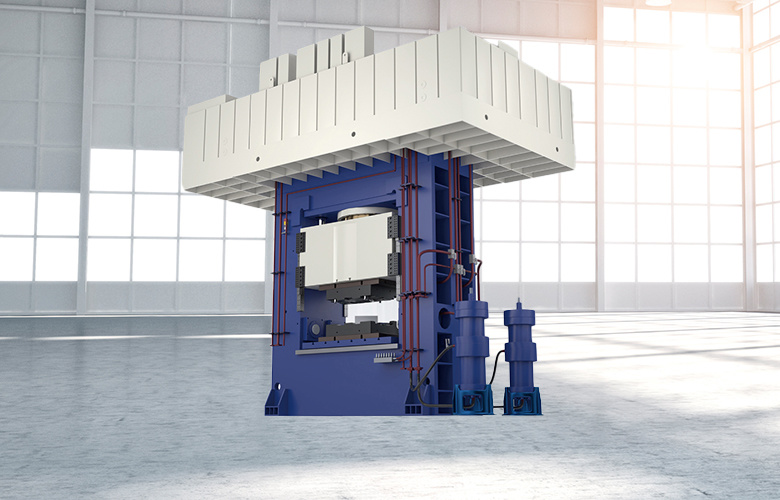

Pneumatic hydraulic clamping system

NC rotary table self-locking system

volumetric automatic lubrication system

Hard rail slide table and power assembly

laser displacement detection system

Automatic chip removal system

MTX micro control system

(Including servo drive system, man-machine control interface, leakage protection device, etc.)

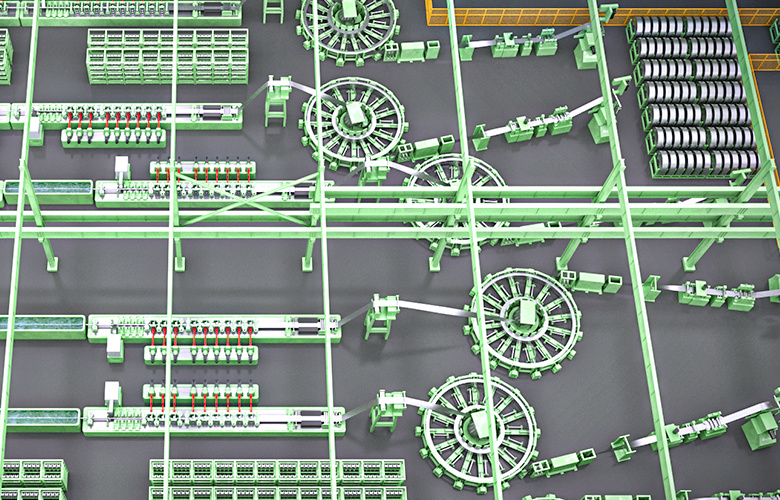

Industry Applications

Milling of Automobile Rear Subframe

The frame is the skeleton of the car, and its accuracy and stability directly affect the overall performance of the car.

The rear subframe milling machine can ensure the dimensional accuracy of the frame through precise cutting and machining

And surface quality, thereby improving the safety and durability of the car.

Technical parameters

| Project | Unit | Parameters |

| Length x Width x Height | mm | 4050 (excluding chip remover) x1750x1650 |

| Total power | KW | 30 |

| Operating voltage | V | Three-phase two-wire 380±5% |

| Pneumatic clamping force | KG | >2000 |

Key words:

Related Products

Welcome your message consultation

*Leave your contact information to get a free product quote