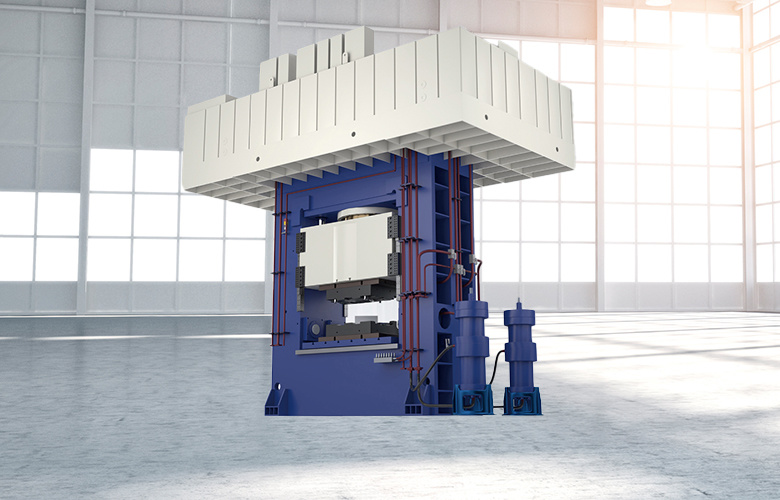

4000T CNC hydraulic forming equipment

Each equipment is equipped with two pressurized cylinders with a maximum pressure of 400MPa, which can process complex workpieces with large deformation and high yield strength;

The pressure control accuracy of the booster cylinder is ± 0.5Mpa, which can fully meet the requirements of the pipe forming pressure accuracy;

The resolution of the oil cylinder displacement sensor is 0.001mm, and the accuracy of the side cylinder during actual control is 0.1mm, which can fully meet the requirements of the filling accuracy when the workpiece is formed;

The oil cylinder adopts one-to-one servo control, the fastest speed can reach 110 mm/s, while the traditional servo valve has a small diameter, and the speed is much faster than that of servo valve control at the same cost.

Category:

Product Description

Product Features

Energy consumption

Energy consumption

Servo motor drive, low power consumption, low noise

Cost

Cost

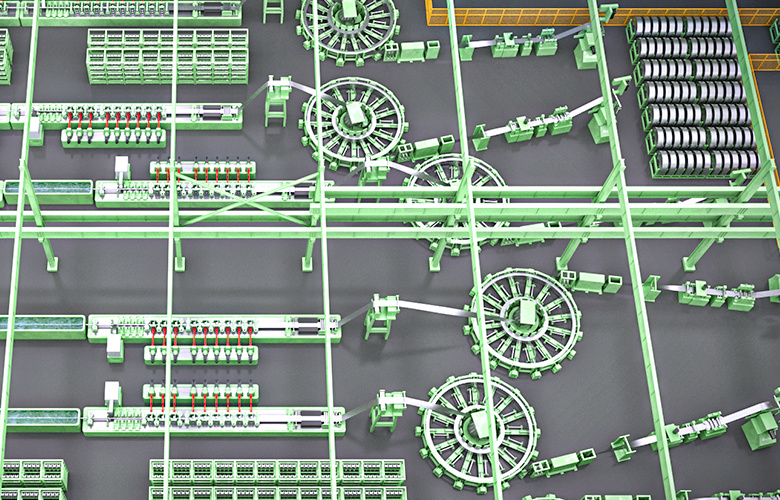

Unmanned production, integrated processing of each process,

Advanced molding process design, high material utilization

Efficiency

Efficiency

Dual cavity processing, each hydraulic forming two sets of products

Intelligent

Intelligent

Servo control system based on Ethercat bus,

High communication speed for efficient processing of data in the production process

Accuracy

Accuracy

Using high-precision hydraulic servo system, the control accuracy is within ± 0.1mm

Technical parameters

| Project |

Unit |

Value/Characteristic |

Remarks |

|

| Nominal force |

KN |

40000 | ||

| Return force |

KN |

≥ 1600 | ||

| Hydraulic system pressure |

MPa |

25 | ||

| Side cylinder force |

KN |

2500x4 | Two on the left and right | |

| Master cylinder stroke |

mm |

600 | ||

| Side cylinder stroke |

mm |

180 | ||

| Maximum mold opening height |

mm |

1350 | ||

| Control accuracy of main cylinder pressing and side cylinder jogging stroke |

mm |

±0.05 | Displacement ruler resolution 0.01mm, Control accuracy guaranteed by user control program |

|

| Center distance of side cylinder |

mm |

830 | ||

| Main motor power |

KW |

2x75 4x63.5 | Double gear pump servo motor | |

| Effective dimensions of workbench |

Left and right |

mm |

2700 | Left and right cylinder surface spacing 2700 |

| before and after |

mm |

1800 | ||

| Mold clamping speed |

Come on down. |

mm/s |

Approximately 300. | |

| Slow down |

mm/s |

28 | No load, 15mm stroke | |

| suppression |

mm/s |

14 | Mold clamping | |

| Return |

mm/s |

Approximately 220. | ||

| Side cylinder speed |

Fast Forward |

mm/s |

100 | No-load |

| Slow Forward |

mm/s |

29 | Load 25MPa,80mm stroke | |

| Return |

mm/s |

90 | No-load | |

| Pressure cylinder speed |

Fast Forward |

mm/s |

49 | No-load |

| Slow Forward |

mm/s |

30 | Load 25MPa,400mm stroke | |

Key words:

laser

Related Products

Welcome your message consultation

*Leave your contact information to get a free product quote