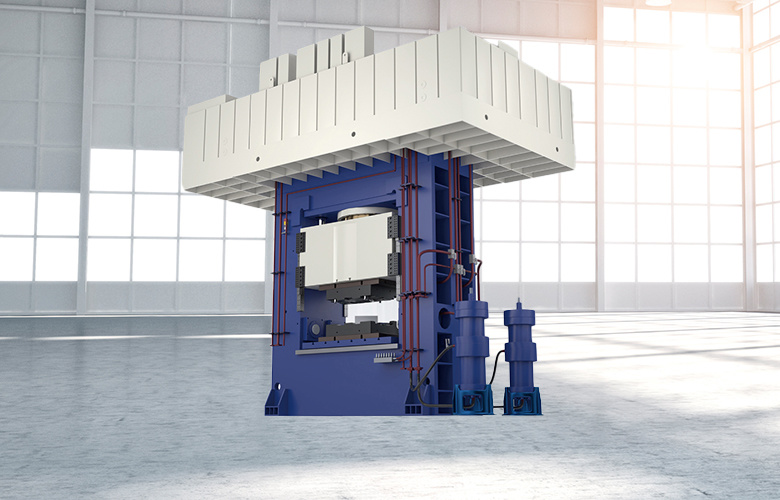

Sixteen-axis double-station laser machining center

Cutting-edge laser technology and advanced digital control technology depth integration, high efficiency double workbench four station, production capacity doubled.

Product Description

Industry Applications

Three-dimensional precision machining of carbon steel, stainless steel, titanium alloy, aluminum alloy and other materials in the fields of automobile manufacturing, aerospace industry, locomotive manufacturing, medical equipment, sheet metal processing, etc.

-

Special-shaped pipe fittings

Automobile chassis parts

motorcycle frame

Automotive exhaust system

Fitness Equipment -

Stamping cover

automobile covering parts

Mold sample

Cab

new energy vehicle -

hot-formed steel

Roof beam

Underbody

Side wall reinforcement plate (A, B, C pillar), front wall panel, etc.

Product Features

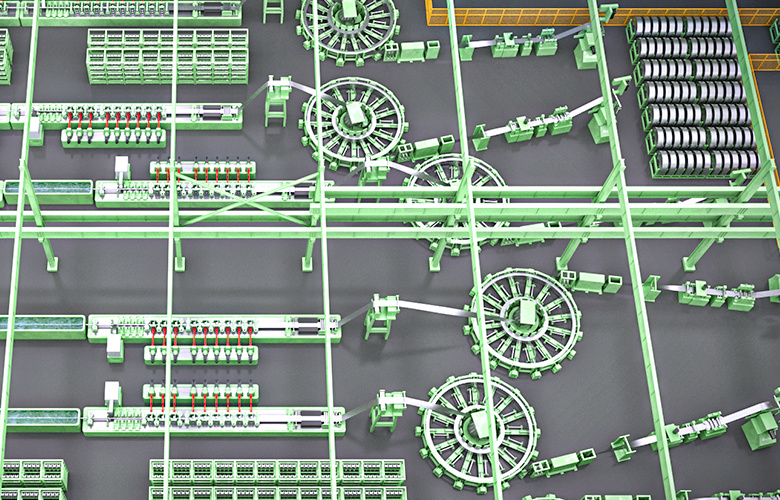

Dual-path independent machining

Usually, the three-dimensional five-axis equipment has only one cutting head and can only carry out five-axis linkage, and the special-shaped pipe fittings need to be clamped twice to complete the processing. JUZI sixteen axis independent dual cutting head and add four external rotating axes. Each external rotation axis can realize six-axis linkage high-precision laser cutting, avoiding the processing error caused by the second clamping.

Dual high-speed follow-up function

Follow-up control is called gap control, which refers to controlling the laser cutting head to maintain a constant distance from the surface of the workpiece during numerical control laser processing, that is to say, with the fluctuation of the surface of the workpiece, the laser cutting head should also adjust its position in real time. Juzhi 16 axis adopts Fanaco's unique HSP high-speed follow-up to ensure the stability of the cutting gap.

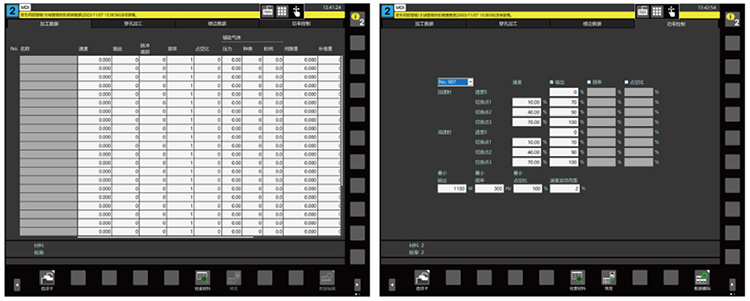

Follow-up control function-dual HSP high-speed follow-up

Efficient Programming

The position of the machine tool and the workpiece in the real environment is converted to 1:1 by software, and there is no need to carry out three-point positioning for program debugging after the tooling is completed, which shortens the time of program debugging;

Adapt fully automatic path optimization, solve collision, limit and other problems to reduce programming difficulty and improve programming efficiency in the process of five-axis machine tool processing and programming;

• Generate a spatial sweep during the movement, record the positions of the cutting head, tooling, etc. during the simulation, and assist in easily defining the interference area. Relying on the working space required for processing, to help create a more optimized fixture design.

Dual path independent process setup

Sixteen axes to achieve dual-channel independent control, dual-channel can correspond to 30 sets of different process parameters, processing parameters change more simply, unique power wave control to avoid corner burrs and over-burning. It is divided into 1-10 processing grades. The higher the processing grade, the higher the accuracy, the slower the speed. On the contrary, the lower the grade, the lower the accuracy, the faster the speed. Different processing levels can be selected on the same pipe fittings to achieve the perfect choice of speed and accuracy.

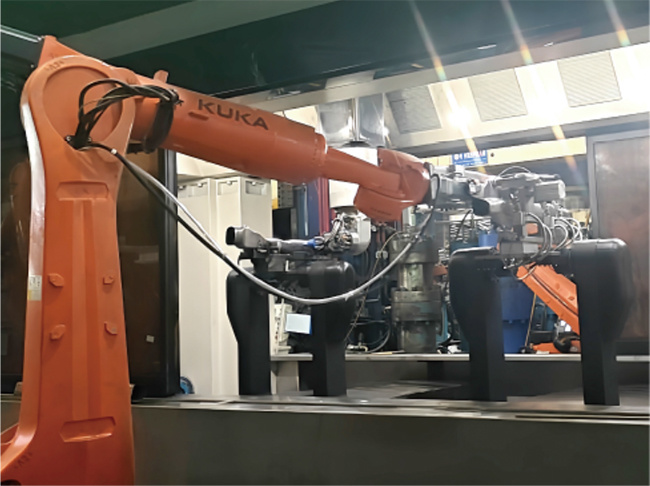

Efficient double-station automatic processing

Realize the loading and unloading of double-station manipulator, saving loading and unloading time and labor cost.

Technical parameters

| Technical Specifications | Parameters | |||||||||||||||

| X1 | X2 | Y1 | Y2 | Z1 | Z2 | A11 | A12 | A21 | A22 | B1 | B2 | C1 | C2 | W1 | W2 | |

| Travel (mm) | 2950 | 2950 | 1380 | 1380 | 730 | 730 | ±180° | ±180° | ±180 | ±180° | ±135 | ±135° | NX360° | NX360° | ±10 | ±10 |

| Maximum speed (m/min) | 120 | 120 | 80 | 80 | 120 | 120 | 120RPM | 120RPM | 120RPM | 120RPM | 120RPM | 120RPM | 120RPM | 120RPM | 20 | 20 |

| Maximum acceleration (10m/s2) |

10 | 10 | 10 | 10 | 10 | 10 | 25 rad/s2 |

25 rad/s2 |

25 rad/s2 |

25 rad/s2 |

125 rad/s2 |

125 rad/s2 |

125 rad/s2 |

125 rad/s2 |

10 | 10 |

| Repeated positioning accuracy (mm) | ±0.025 | ±0.025 | ±0.015 | ±0.015 | ±0.015 | ±0.015 | ±0.01° | ±0.01° | ±0.01° | ±0.01° | ±0.01° | ±0.01° | ±0.01° | ±0.01° | ±0.025 | ±0.025 |

| Motor power (KW) | 5 | 5 | 5.5 | 5.5 | 5.5 | 5.5 | 0.62 | 0.62 | 0.62 | 0.62 | 0.37 | 0.37 | 0.75 | 0.75 | 0.2 | 0.2 |

| Laser power (W) | 6000 | |||||||||||||||

| Maximum mass of tooling (KG) | 100 (Note: the center of mass of the tooling is 200mm from the center of the axis) | |||||||||||||||

| Length x Width x Height (mm) | 6800 × 4300 × 5200 | |||||||||||||||

| Total weight (T) | about 30 | |||||||||||||||

Key words:

Related Products

Welcome your message consultation

*Leave your contact information to get a free product quote