High-speed multi-axis linkage intelligent pipe bender

Product Description

Function Description

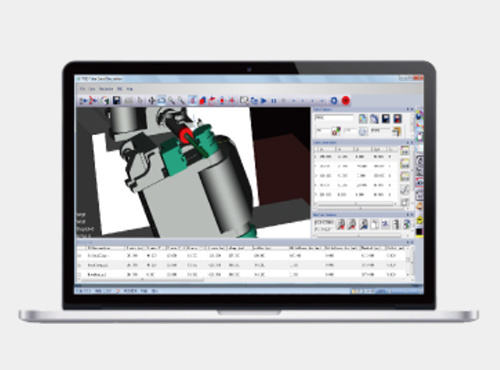

Can realize simulation, bending and other integrated processing;

It can realize the structural strength analysis of pipe fittings, the simulation of pipe fittings processing, and the determination of the interference area of the processing process;

Easy to change the mold, can be installed up to a total of 8 layers of double-head mold, to achieve complex pipe fittings disposable elbow;

It can realize the functions of simulation processing, online detection, curve recording, automatic lubrication, real-time monitoring and fault alarm in the production process.

Industry Applications

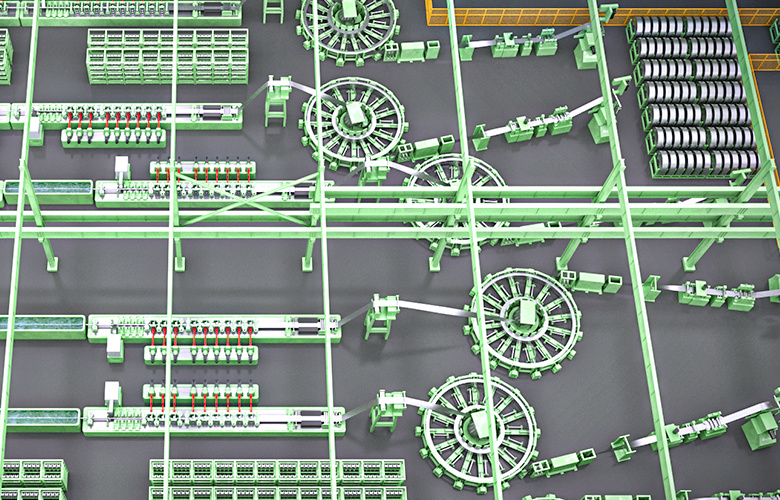

Processing Technology of Bend Pipe

Three-dimensional bending of carbon steel, stainless steel, copper, aluminum alloy and other materials in automobile manufacturing, aerospace industry, medical equipment, petrochemical industry, household industry and other fields.

-

Automobile manufacturing field

Automobile chassis parts

motorcycle frame

Automotive exhaust system

Fitness Equipment

-

Mechanical manufacturing field

All kinds of metal pipes

Hydraulic system

Pneumatic system

Air conditioning line

-

Other areas

Aerospace

Petrochemical

Medical Devices

Home industry

Product Introduction

-

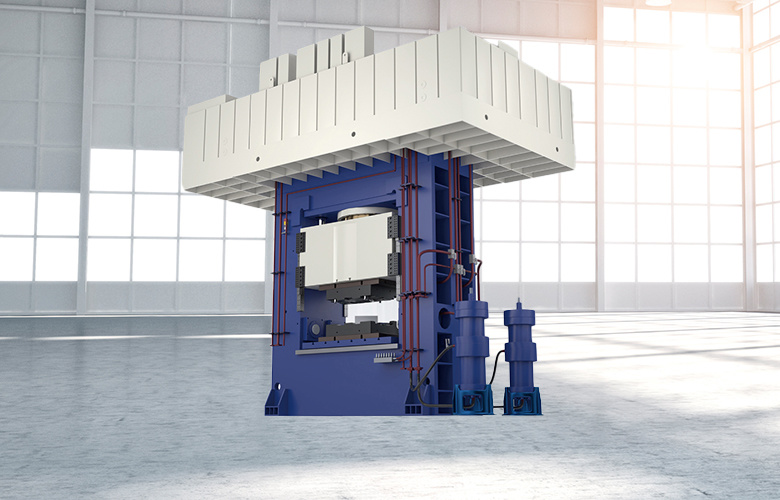

Equipment composition

Bend rotating arm, tube blank rotation, auxiliary push fixed cantilever, tube blank support, head rotation, auxiliary push of residual material, head movement, core pulling, feeding trolley, control system, tube blank clamping

-

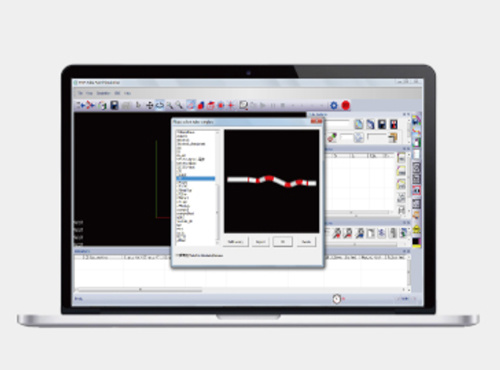

software operating system

Based on the secondary development of WINDOW platform, it has the characteristics of automatic simulation processing, automatic weld recognition, automatic clamping force detection, automatic loading and unloading, automatic lubrication system, automatic abnormal alarm, real-time operation monitoring, remote help and so on.

-

Transmission parts

High precision ball screw

Low backlash reducer

High precision linear guide

-

virtual simulation

Online simulation can be used to automatically calculate the optimal bend path to avoid interference areas in the machining process.

-

German Beifu Control System

Control computer

Drive

Servo motor

-

Other Hardware

Germany Egus drag chain cable

Schneider Low Voltage Electrical Components

sealed cabinet with air conditioner

Technical parameters

| Project | Unit | Value/Characteristic | |

| Appearance specification | Weight (including control console) | KG | 9000 |

| Dimensions (l * d * h) | mm | 4600x2400x2000mm | |

| Color | - | Black, white orange pattern spray | |

| Working environment | Studio temperature | ℃ | 5/ 40 |

| Storage temperature | ℃ | -25/ 55 | |

| Humidity at maximum phase | % | 5-75(mx.for24h) | |

| Electrical System | Voltage | V | 380 soil 5% |

| Power supply type | - | three-phase two-wire system | |

| Frequency | Hz | 50±1% | |

| Total motor power | KW | 65 | |

| Rated current | A | 100 | |

| Lubrication system | Lubrication system tank capacity | L | 3 |

| Lubrication system pressure | MPa | 2.5max | |

| Mandrel lubrication system box capacity | L | 8 | |

| Mandrel lubrication system pressure | MPa | 3maX | |

| Technical parameters | Max. Bend Diameter | mm | 100 |

| Maximum bending radius (excluding push bending) | mm | 200 | |

| Maximum tube length | mm | 2300 | |

| Maximum feeding speed | mm/s | 700 | |

| Maximum bending speed | °/sec | 70 | |

| Maximum speed of tube rotation | °/sec | 300 | |

| Maximum Nose Moving Speed | mm/s | 730 | |

| Maximum rotation speed of the machine head | °/sec | 100 | |

| Maximum feeding speed of follower die | mm/s | 160 | |

| Maximum speed of residual material | mm/s | 160 | |

| Repeated positioning accuracy | mm ° |

Feeding = ± 0.03 Nose Translation = ± 0.03 Boosting = ± 0.02 Residual Material Push = ± 0.02 Bend = ± 0.03 Nose Rotation = ± 0.03 Billet Rotation = ± 0.03 |

|

| Maximum output torque of elbow | N.M | 20000 | |

| Maximum output force of feeding | KN | 80 | |

| Maximum core pulling force | KN | 80 | |

| Max. clamping force of main clamp | KN | 250 | |

| Maximum clamping force of auxiliary clamp | KN | 200 | |

| Boosting maximum pushing force | KN | 60 | |

| Maximum push-out force of residual material | KN | 60 | |

| Maximum bend angle | ° | 180 | |

| Feeding stroke | mm | 2050 | |

| Nose travel | mm | 1150 | |

| Core-pulling stroke | mm | 300 | |

| Boost stroke | mm | 150 | |

| Residual material push-out stroke | mm | 230 | |

| Main clamp clamping stroke | mm | 170 | |

| Clamping stroke of auxiliary clamp | mm | 170 | |

Key words:

laser

Related Products

Welcome your message consultation

*Leave your contact information to get a free product quote